Static test load

Pile testing by IPM Impuls Pfahlmessung GmbH.

To learn more, please click here.

The principle

the static test load

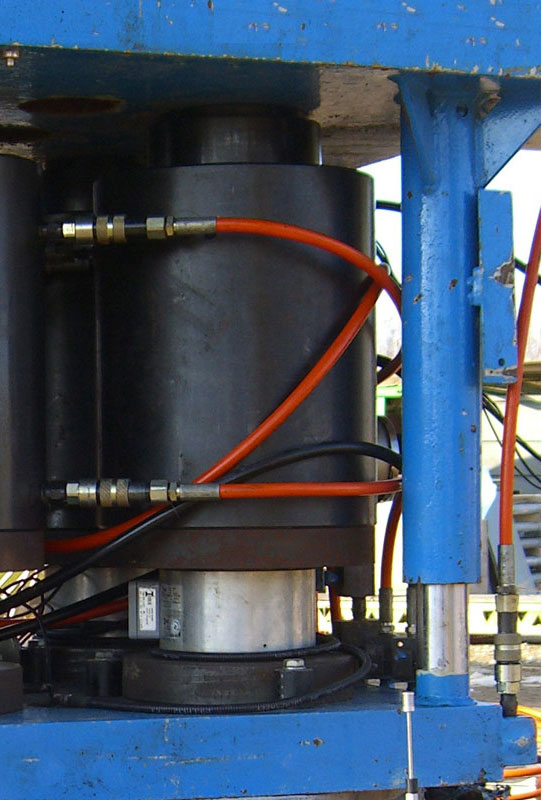

A hydraulic system is used to generate the load, consisting of a power unit up to 700 bar, with electronically controlled constant-pressure control and several identical two-way presses. The exact force is measured by calibrated load cells. Steel trusses and reaction piles are used as abutments. Dead loads are also possible for low loads.

The vertical and horizontal pile displacements are measured with electrical precision dial gauges with a resolution of 1/100mm. Strain gauges, chain extensometers and pile foot load cells can be used to determine skin friction and peak pressure.

Our Services

Services:

- Consulting, planning, optimization, concept

- Statics, certificates, calibration

- Provision of the load structure

- Provision of electrical hydraulic system

- Delivery / installation of the pile measurement sensors

- Assembly work

- Implementation according to EA piles or international standards

- Documentation / Evaluation

Equipment:

- various hydraulic systems

- various steel trusses up to 40MN

- computer-controlled measuring technique

- Highly accurate calibrated displacement gauges

- calibrated force measurement

- Pile instrumentation

Implementation:

- Standard (2 load cycles)

- high requirements (jacket friction and peak pressure)

- cyclical loads

- Long-term exposure

Pile instrumentation:

- pile foot – pressure load cell

- Deformation transducer for shell friction

- Chain extensometer

- Chain inclinometer

Get in touch with us:

+49 (0) 3621 70 30 31

Exhibition equipment

Steel trusses

Various steel trusses are available.

- For large bored piles (≥ Ø 120 cm), type HE1000 reinforced in S460; test loads up to 40 MN

- For piles (≤ Ø 120 cm), type HE700 reinforced in S460; test loads up to 10 MN

- Load crown; test loads up to 20 MN

- Test loads with dead load; test loads up to 6 MN

Force and pressure measurement

The direct force measurement is carried out with identically calibrated load cells directly under the presses. The pressure of the hydraulic system is measured with a calibrated pressure transmitter and a precision manometer. Thus the press pressure can also be converted into a compressive force in kN.

Dial gauges for measuring pile head displacements

The vertical displacement of the test pile is measured with electronic dial gauges with laser technology (accuracy 0.02 %) or precision probes (accuracy <6 µm), as well as redundant cal. electr. precision dial gauges (accuracy <10 µm). Electronic dial gauges are also used for the displacement of the horizontal inclination of the test pile and the displacement of the reaction piles.

Pile instrumentation

Determination of shell friction and peak pressure

For the determination of skin friction and peak pressure, transducers from Geokon (USA), Glötzl and Bauer (Germany) are used.

The instruments are specially developed for this application and are accordingly calibrated, robust, temperature-compensated and with high accuracy. The compression or elongation is effected by a “vibrating string”. Here the concrete compression is converted into an electrical frequency and is independent of cable lengths and electrical interference. By means of a multiplexer, data logger and the corresponding software program, the values are permanently evaluated and archived during the execution.

- Rebar Strainmeters Sister Bars or Concrete Embedment Strain Gages for the determination of shell friction and peak pressure

- Peak pressure load cells (electric or hydraulic) for determining the peak pressure

- Chain extensometer for the determination of shell friction and peak pressure

Determination of the bending line for horizontal test loads

To determine the bending line at a horizontal sample load, the transverse displacements are continuously and automatically recorded by means of a chain inclinometer with a maximum of 8 measuring planes.

Pressure test load

The test loads are carried out according to DIN1054:2005 and the “Recommendations of the Piles Working Group” EA – Piles of the DGGT e.V. A steel cross beam and reaction piles or reaction anchors are used as abutments for a compression test loading. Primarily 2 reaction piles are used, however, depending on the building ground up to 16 reaction anchors are also possible. Dead loads are also possible for low loads. A hydraulic system is used to generate the load, consisting of a power unit up to 700 bar, with electronically controlled constant-pressure control and several identical two-way presses.

The exact force is measured by calibrated load cells. The vertical and horizontal pile displacements are measured with electrical precision dial gauges with a resolution of 1/100mm. The test load is computer-controlled and carried out at exact intervals. All parameters e.g. load steps, paths, times, cycles, creep mass etc. are specified in the load program before the measurement. Arranged changes during the measurement are possible at any time. The subsequent load program is fully automatic, with occasional necessary control queries and automatic documentation of all measurement data.

results are:

Trial pole:

1. diagram load displacement

2. diagram time shift

3. diagram load steps

4. diagram creep dimension

5. x – y Displacement

6. pile integrity

7. Possible skin friction and peak pressure

Reaction peg:

8th diagram: load-suspension

9. pile integrity

For increased and high requirements, the test pile is equipped with calibrated measuring sensors before pile production. The result is the determination of skin friction and peak pressure.

See also: Pile instrumentation

Tensile test load

The test loads are carried out according to DIN1054:2005 and the “Recommendations of the Piles Working Group” EA – Piles of the DGGT e.V. A steel cross beam and reaction piles or the subsoil are used as abutments for a compression test load. To generate the load, a hydraulic system is used, consisting of a power unit up to 700 bar, with electronically controlled constants and several identical two-way presses. The exact force is measured by calibrated load cells.

The vertical and horizontal pile displacements are measured with electrical precision dial gauges with a resolution of 1/100mm. The test load is computer-controlled and carried out at exact intervals. All parameters e.g. load steps, paths, times, cycles, creep mass etc. are specified in the load program before the measurement. Arranged changes during the measurement are possible at any time. The subsequent loading program is fully automatic, with occasional necessary control queries and automatic documentation of all measurement data.

results are:

Trial pole:

1. diagram load displacement

2. diagram time shift

3. diagram load steps

4. diagram creep dimension

5. x – y Displacement

6. pile integrity

7. Possible skin friction

Reaction peg:

8. load-settlement diagram

9. pile integrity

For increased and high requirements, the test pile is equipped with calibrated measuring sensors before pile production. The result is the determination of the skin friction.

See also: Pile instrumentation

Horizontal test load

The test loads are carried out according to DIN1054:2005 and the “Recommendations of the Piles Working Group” EA – Piles of the DGGT e.V. In case of a horizontal test load, a steel truss and a reaction pile or a non-sliding abutment serve as a support. A hydraulic system is used to generate the load, consisting of a power unit up to 700 bar, with electronically controlled constants and a press. The exact force is measured by calibrated load cells.

The measurement of the horizontal pile displacements is carried out with electrical precision dial gauges with a resolution of 1/100mm. The test load is computer-controlled and carried out at exact intervals. All parameters e.g. load steps, paths, times, cycles, creep mass etc. are specified in the load program before the measurement. Arranged changes during the measurement are possible at any time. The subsequent load program is fully automatic, with occasional necessary control queries and automatic documentation of all measurement data.

results are:

Test pile / reaction pile:

1. diagram load shift

2. diagram time shift

3. diagram load steps

4. determination of pile head inclination

5. x – y Displacement

6. pile integrity

7. possible bending line

To determine the bending line at a horizontal sample load, the transverse displacements can be continuously and automatically recorded by means of a chain inclinometer.

See also: Pile instrumentation

Cyclical test load

The test loads are carried out according to DIN1054:2005 and the “Recommendations of the Piles Working Group” EA – Piles of DGGT e.V.

Building project

with cyclical test load:

1. ENBW Baltic 2 wind farm

Steel pile ø 150 cm

up to 15 MN compression and tensile load

1,000 cycles – load change 500 kN

15 cycles – load change 15 MN with extensometer

3. Jade – Weser – Port Wilhelmshaven

In-situ driven concrete pile ø 61 cm

Pressure and tensile load

500 cycles – load change 500 kN

with pile instrumentation

3. ICE fast track

Cologne-Rhine/Main – Renovation of the noise protection walls

GEWI pile ø 50 mm

cyclical load

10.000 cycles – load change 40 kN

Test load on anchors and micropiles

The test loads are carried out according to DIN EN 1537 and the “Recommendations of the Piles Working Group” EA – Piles of DGGT e.V.

Building project

with test loads on anchors and micropiles:

1. Rhine Port Bonn

injection piles – round steel anchors

Pitch = 15 degrees

up to 1.700 kN tensile load

3. Siemens AG – Energy Sector – Berlin

Weight pole Ø 28

Inclination = vertical

3. INNNES Warehouse Island

Weight pole Ø 63,5

Inclination = vertical

References

Our references of static test loads at a glance:

2018 - Number of test loadings: 68

50 compression / 18 pieces tensile test loads

4 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- EÜ Stetten

- Herten AGR – Foundation for new heat exchangers

- EÜ Vineyards / EÜ Seestrasse – Frankfurt/Oder

- Neubrandenburg – Bypass

- Brunsbüttel – New construction 5th lock chamber

- Berlin – A 114, BW 19212

- Hamburg – Station new building Elbbrücken

- Buxtehude – Overpass K 40 over the A26

- Ingolstadt – Congress Hotel KHI

- Regensburg – A3 Nuremberg-Passau 6-lane extension

Foreign:

- Oslo – Norway – HOVEDBANEN OSLO S AREA 120

- Geneva – Switzerland – Opals

- Linz – Austria – New Bruckner Tower

2017 - Number of test loads: 80 pieces

57 compression / 19 pieces tension / 4 pieces horizontal test loads

10 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- Stuttgart 21

- Wismar – Port expansion Seaport 2.BA

- Coburg – EÜ Füllbach – rehabilitation of the foundation

- Gleesen lock system – BAM research anchor

- Berlin – CCHPP Marzahn – SIEMENS combined heat and power plant

- Brunsbüttel – New construction 5th lock chamber

- Samtens / Bergen – B96 N, BL 05, BW 02

- Düsseldorf – U81 1st BA, Flughafenstraße

- Hamburg – New construction of the urban railway station – Elbbrücken

Foreign:

- Farmsum – Netherlands – Waste to Energy Delfzijl

- Linz – Austria – A7 Mühlkreis motorway – Voest bridge

- Reykjavík – Iceland – INNNES Warehouse Iceland

2016 - Number of test loads: 69 pieces

34 compression / 35 pieces tensile test loads

9 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- Buxtehude – BAB 26 Stade-Hamburg – BW 8090 – Estequerung

- Bremerhaven – Industrial area Luneort – Development Luneplate

- Hamburg – Securing Pilotage Yard

- Berlin – Axel Springer Campus

- Samtens – bridge in the course of the B 96n – Sehrowbachtal bridge

- Stuttgart 21

- Old Exhibition Centre Leipzig – Portikus / Exhibition Hall 12 / City Archive

Foreign:

- Oslo – Norway – HOVEDBANEN OSLO S AREA 120

2015 - Number of test loadings: 54 pieces

30 compression / 18 tension / 6 horizontal test loads

13 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- Stadtwerke Kiel AG – New construction of a gas engine cogeneration plant

- Hamburg – New railway bridge Kattwyk

- Frankfurt am Main – Terminal 3 Fraport

- Wilhelmshaven – Naval port facility – replacement of the west quay

- Stuttgart 21

- Dessau – Mulde bridge

- Deggendorf – MAN Deggendorf Diesel & Turbo SE

Foreign:

- Bihac – Bosnia and Herzegovina – Wastewater Treatment Plant

- Vienna – Austria -Austria Campus

2014 - Number of test loads: 84 pieces

53 compression / 14 tension / 17 horizontal test loads

13 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- Stuttgart 21

- Closing the gap Berlin Spandau – Ruhleben

- ABS Paderborn – Chemnitz – New construction EÜ Rodabrücke

- Samtens-Rügen – BW 2852-06 Bridge in the course of the B96n

- Hamburg – Waltershofer bridges – Altenwerder Damm

- Potsdam-South – combined heat and power plant

- Schwerin – New construction of the BAB A 14, VKE 7

- BASF Ludwigshafen – B518

Foreign:

- Kazakhstan – Tengiz – Tengizchevroil – KPJV – Project 3GP 3GI

2013 - Number of test loadings: 36 pieces

29 compression / 7 pieces tension test loads

13 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- Bielefeld – BAB A33 – BW 602

- Limburg – Lahn Valley Bridge

- Mukran – Rügen – Outlet structure ferry port

- Hochmosel crossing Moselle bridge

- Stuttgart 21

Foreign:

- Geneva – Switzerland – Aéroport International Genève – AIG aile_est

- Vienna – Austria – REWE Ost full container warehouse

- Zagreb – Croatia – IKEA

2012 - Number of test loadings: 36 pieces

22 compressive / 11 pieces tensile / 3 pieces horizontal test loads

17 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- B 96 n feeder road Stralsund / Rügen – Building 2851

- Berlin – Berlin Palace – Humboldt Forum

- Stuttgart 21

- Elbe port Brunsbüttel

- BAB A3 – Würzburg-Heidingsfeld BW288a

- New construction B96n – feeder road Stralsund / Rügen

Foreign:

- BWT construction phase 2 – Mondsee Austria

- Logistics Center SPAR – Ebergassing Austria

2011 - Number of test loads: 47 pieces

34 compression / 10 pieces tension / 3 pieces horizontal test loads

25 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- ENBW Wind farm Baltic 2

- Herzberg – bridge Schwarze Elster

- New locks DEK-North

- BAB A31 AS Riepe – Neermoor

- Combined cycle power plant – Knapsack II

- Spremberg – New construction of EBS power plant

- Wilhelmshaven – Jade Weser Port

Foreign:

- Lenzing AG – Austria

- Sava Most Belgrade – Serbia

- Kühnsdorf – Austria

2010 - Number of test loads: 28 pieces

20 compression / 8 pieces tension test loads

4 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- B249 Mulhouse – DB AG

- Essen – Water treatment plant

- Hamburg – Finkenwerder bypass

- BAB A72 VKE 356.3 Rathendorf

- Elbeu – Mittellandkanal DB AG canal overpass

- Wilhelmshaven – 800 MW power plant

Foreign:

- Linz – S10 Mühlviertler expressway – Austria

2009 - Number of test loadings: 22 pieces

10 compression / 11 tension / 1 horizontal test load

6 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- Bad Oeynhausen – BW 15 + BW 22

- NBS Erfurt-Halle/Leipzig EÜ-Unstruttal

- Cologne-Mülheim – DB AG EÜ over the A3

- Ludwigshafen – BASF

- BAB A72 – viaduct Zedtlitzer Grund

- Wilhelmshaven – Jade Weser Port

Foreign:

- Warisoulx Belgium – Enercon

2008 - Number of test loadings: 35 pieces

26 compression / 5 pieces tension / 4 pieces horizontal test loads

4 pieces with pile instrumentation (skin friction / peak pressure / bending line)

Extract Germany:

- Lünen – hard coal-fired power plant

- WP Sulingen WEA Enercon

- Ludwigshafen – Rhine Gallery

- Flöha – DB Bridge

- Dessau – Muldequate crossing – DB line

- Hanover – EÜ bridge MLK

- Bremerhaven – Kaiserschleuse